R&D

R&D

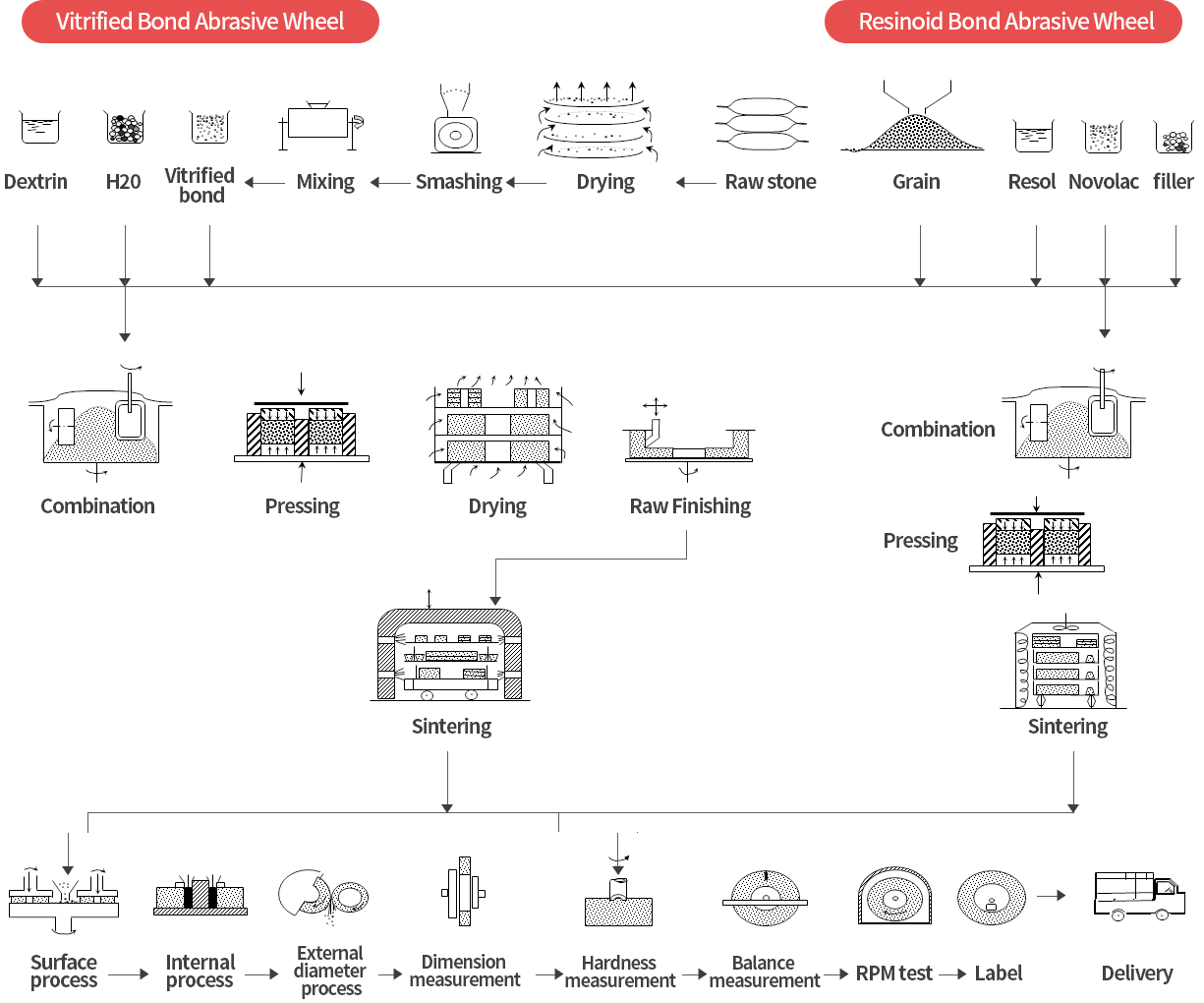

Production Line

Marking of Grinding wheels

- WAⓐ

- 60ⓑ

- Jⓒ

- 6ⓓ

- Vⓔ

- 1A

ⓐ Abrasives wheels manufactured according to the manufacturing method

- A = Alundum

- WA = White Alundum

- GC = Green Carborundum

- SG = ∝-Al2O3 manufactured by the sol-gel method

- PA = Pink Alundum

- SA = Single Crystaline Alundum

- C = Carborundum

ⓑ Represents a particle size of 60 mesh (250㎛)

- Assembly = 10 ~ 24mesh

- Fine grain = 80 ~ 220mesh

- Neutrality = 30 ~ 60mesh

- Microfine = 240 ~ 800mesh

ⓒ Bonding degree of grinding wheels

- E, F, G = the most soft

- I, M, N, O = Medium

- T, U, V, W, X, Y, Z = very hard

- H, I, J, K = soft

- P, Q, R, S = hard

ⓓ Organization of grinding wheel

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Compactness | Normal | Sloppy | |||||||||||

ⓔ Type of bond

- V = Vitrified

- B = Resinoid

Foundation of Grinding wheels

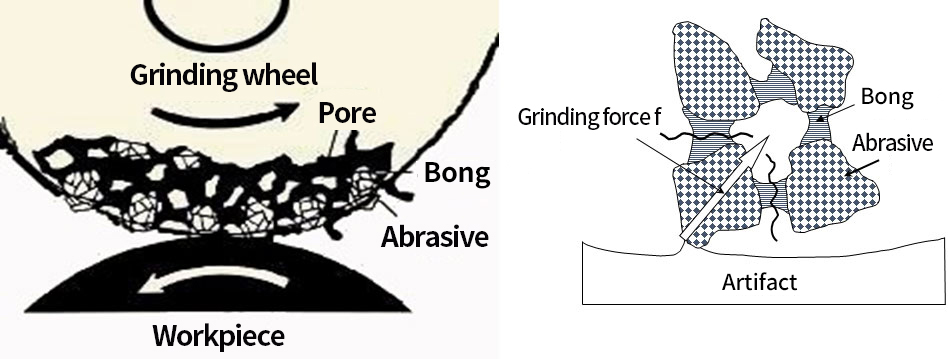

Components of grinding wheels

- 1. Abrasive : The role of cutting the workpiece with the cutting edge.

- 2. Binder : The role of binding and protecting the abrasive grains.

- 3. Pore : It is between the abrasive grain and the binder, and the role to escape the cutting powder.

[ The location of the elements that make up the grinding wheels ]

Type and characteristics of grain

Abrasive

Abrasive is an artificial synthetic material that acts as a cutting edge in a grinding wheel.

| Type | Color | Mark | Name | Manufacturing method | Usage | |

|---|---|---|---|---|---|---|

| Ceramic abrasive (AI203) | Blue (opaque) | SS | CUBITRON | Ceramic inorganic material produced through the SOL-GEL process (process) | Grinding of difficult-to-cut materials such as soft, high carbon steel and stainless steel | |

| White (opaque) | SG | HTB | ||||

| Silicon carbide (SiC) | black | C | Black Silicon Carbide | Crystallization of silica and carbon material by crystallization in an electric resistance furnace | Casting, non-metal, abrasive cloth, refractory, crystal, stone | |

| Green | GC | Green Silicon Carbide | It is made by crystallizing a carbon material having a higher purity than the raw material by the same method | Cemented carbide, refractory | ||

Types and characteristics of abrasives

| Type | Color | Mark | Name | Manufacturing method | Usage | |

|---|---|---|---|---|---|---|

| Molten alumina (Al2O3) | Brown | A | Regular Aluminium Oxide | Brown crystals pulverized by melting bauxite in an electric furnace | General steel, grinding cloth, optical grinding, semiconductor grinding, refractory, etc. | |

| White | WA | White Aluminium Oxide | Crystal by melting and pulverizing alumina by the Basya method | Synthetic steel, abrasive paper, special refractory, etc. | ||

| Light gray | HA | Single crystal Aluminium Oxide | An incoat made by adding and dissolving sulfur, etc. to an alumina compound is submerged in water and separated by particles | Light grinding tool steel of alloy steel, special steel | ||

| MA | ||||||

| 32A | ||||||

| SA | ||||||

| Pink | PA | Pink Aluminium Oxide | Same as WA product, but melted and crystallized by adding a little Cr203 to give it properties | Internal grinding and gear grinding of general heat treated steel | ||

| RA | ||||||

| Brown | TA | Collection of grains (集結晶砥粒) | It is the same as the manufacturing method of brown molten alumina grinding material, but makes the crystal large by making a difference in the cooling speed. | Slab Billet Heavy Duty grinding | ||

| Gray | Z | Zirconia Aluminium Oxide | Alumina and zirconia are mixed and pulverized by melt cooling under special conditions | Super heavy grinding of steel, casting, and steel | ||